- 高精度、高刚性、高效率

- 低惯性、低振动、低噪音、低温升

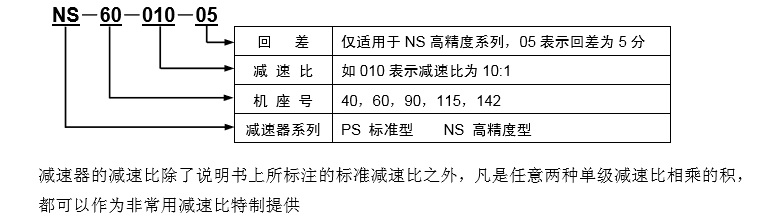

PS系列是在多年技术开发的基础上,通过引进国际先进技术、推出的精密行星齿轮减速器系列。该系列减速器采用高精度硬齿面磨齿齿轮,具有 高精度、高刚性、高负载、高效率,低惯性、低振动、低噪音、低温升等特点,不仅可适配于我公司自有“森创”品牌的各种伺服电机及步进电机,也可适用其他各种品牌的电机产品。

NS系列减速器是基于PS系列的高精度型减速器,回差精度高、适用于某些对精度要求比较高的特殊场合。

|

技术参数

|

单位

|

减速比

|

PS40

|

PS60

|

PS90

|

PS115

|

PS142

|

|

|

NS40

|

NS60

|

|||||||

|

额定输出转矩

|

N·m

|

单级

|

3

|

|

45

|

110

|

220

|

550

|

|

4

|

20

|

45

|

110

|

220

|

550

|

|||

|

5

|

20

|

45

|

110

|

220

|

550

|

|||

|

7

|

|

40

|

80

|

170

|

400

|

|||

|

9

|

20

|

|

|

|

|

|||

|

10

|

|

40

|

80

|

170

|

400

|

|||

|

双级

|

9

|

|

45

|

110

|

220

|

550

|

||

|

12

|

|

45

|

110

|

220

|

550

|

|||

|

15

|

|

45

|

110

|

220

|

550

|

|||

|

16

|

20

|

45

|

110

|

220

|

550

|

|||

|

20

|

20

|

45

|

110

|

220

|

550

|

|||

|

21

|

|

45

|

110

|

220

|

550

|

|||

|

25

|

20

|

45

|

110

|

220

|

550

|

|||

|

28

|

|

45

|

110

|

220

|

550

|

|||

|

30

|

|

45

|

110

|

220

|

550

|

|||

|

35

|

|

45

|

110

|

220

|

550

|

|||

|

36

|

20

|

|

|

|

|

|||

|

40

|

|

45

|

110

|

220

|

550

|

|||

|

45

|

20

|

|

|

|

|

|||

|

49

|

|

45

|

110

|

220

|

550

|

|||

|

50

|

|

45

|

110

|

220

|

550

|

|||

|

70

|

|

40

|

80

|

170

|

400

|

|||

|

81

|

20

|

|

|

|

|

|||

|

100

|

|

40

|

80

|

170

|

400

|

|||

|

极限输出转矩

|

N·m

|

|

额定输出转矩的2倍

|

|||||

|

输入端转动惯量

|

kg·cm2

|

单级

|

3

|

|

0.28

|

1.11

|

4.64

|

15.98

|

|

4

|

0.03

|

0.27

|

0.98

|

4.3

|

14.28

|

|||

|

5

|

0.03

|

0.27

|

0.96

|

4.24

|

13.98

|

|||

|

7

|

|

0.27

|

0.96

|

4.22

|

13.86

|

|||

|

9

|

0.03

|

|

|

|

|

|||

|

10

|

|

0.27

|

0.95

|

4.21

|

13.83

|

|||

|

双级

|

9

|

|

0.28

|

1.11

|

4.64

|

15.98

|

||

|

12

|

|

0.27

|

0.95

|

4.3

|

14.28

|

|||

|

15

|

|

0.27

|

0.96

|

4.24

|

13.98

|

|||

|

16

|

0.03

|

0.27

|

0.96

|

4.24

|

13.98

|

|||

|

20

|

0.03

|

0.27

|

0.96

|

4.24

|

13.98

|

|||

|

21

|

|

0.27

|

0.96

|

4.24

|

13.98

|

|||

|

25

|

0.03

|

0.27

|

0.96

|

4.24

|

13.98

|

|||

|

28

|

|

0.27

|

0.96

|

4.21

|

13.83

|

|||

|

30

|

|

0.27

|

0.95

|

4.21

|

13.83

|

|||

|

35

|

|

0.27

|

0.96

|

4.21

|

13.83

|

|||

|

36

|

0.03

|

|

|

|

|

|||

|

40

|

|

0.27

|

0.95

|

4.21

|

13.83

|

|||

|

45

|

0.03

|

|

|

|

|

|||

|

49

|

|

0.27

|

0.95

|

4.21

|

13.83

|

|||

|

50

|

|

0.27

|

0.95

|

4.21

|

13.83

|

|||

|

70

|

|

0.27

|

0.95

|

4.21

|

13.83

|

|||

|

81

|

0.03

|

|

|

|

|

|||

|

100

|

|

0.27

|

0.95

|

4.21

|

13.83

|

|||

|

抗扭刚度

|

N·m /arcmin

|

|

3

|

|

1.3

|

5.5

|

14

|

28

|

|

4

|

0.35

|

1.3

|

5.5

|

14

|

28

|

|||

|

5

|

0.35

|

1.3

|

5.5

|

14

|

28

|

|||

|

7

|

|

1.3

|

4

|

14

|

28

|

|||

|

9

|

0.35

|

|

|

|

|

|||

|

10

|

|

1.3

|

4

|

10

|

28

|

|||

|

双级

|

9

|

|

1.3

|

5.5

|

14

|

28

|

||

|

12

|

|

1.3

|

5.5

|

14

|

28

|

|||

|

15

|

|

1.3

|

5.5

|

14

|

28

|

|||

|

16

|

0.35

|

1.3

|

5.5

|

14

|

28

|

|||

|

20

|

0.35

|

1.3

|

5.5

|

14

|

28

|

|||

|

21

|

|

1.3

|

5.5

|

14

|

28

|

|||

|

25

|

0.35

|

1.3

|

5.5

|

14

|

28

|

|||

|

28

|

|

1.3

|

5.5

|

14

|

28

|

|||

|

30

|

|

1.3

|

4.75

|

12

|

28

|

|||

|

35

|

|

1.3

|

4.75

|

14

|

28

|

|||

|

36

|

0.35

|

|

|

|

|

|||

|

40

|

|

1.3

|

4.75

|

14

|

28

|

|||

|

45

|

0.35

|

|

|

|

|

|||

|

49

|

|

1.3

|

4.75

|

14

|

28

|

|||

|

50

|

|

1.3

|

4.75

|

12

|

28

|

|||

|

70

|

|

1.3

|

4

|

12

|

28

|

|||

|

81

|

0.35

|

|

|

|

|

|||

|

100

|

|

1.3

|

4

|

10

|

28

|

|||

|

额定轴向负载

|

N

|

转速30rpm

|

1696

|

3192

|

4656

|

8547

|

17627

|

|

|

转速50rpm

|

1430

|

2693

|

3928

|

7210

|

14870

|

|||

|

转速100rpm

|

1134

|

2135

|

3114

|

5717

|

11791

|

|||

|

转速150rpm

|

992

|

1867

|

2723

|

5000

|

10310

|

|||

|

转速300rpm

|

787

|

1482

|

2161

|

3968

|

8184

|

|||

|

转速500rpm

|

664

|

1251

|

1824

|

3349

|

6907

|

|||

|

转速1000rpm

|

527

|

992

|

1447

|

2656

|

5478

|

|||

|

回差(空载)

|

arcmin

|

PS系列单级

|

8

|

6

|

5

|

5

|

5

|

|

|

PS系列双级

|

15

|

10

|

8

|

8

|

8

|

|||

|

NS系列单级

|

6

|

5

|

|

|

|

|||

|

NS系列双级

|

10

|

9

|

|

|

|

|||

|

噪音(空载)

|

dB(A)

|

|

58

|

60

|

62

|

67

|

72

|

|

|

额定输入转速

|

rpm

|

|

3000

|

2000

|

||||

|

3000

|

2000

|

|||||||

|

3000

|

|

|||||||

|

最高输入转速

|

rpm

|

|

5000

|

3000

|

||||

|

5000

|

3000

|

|||||||

|

5000

|

|

|||||||

|

满载效率

|

|

单级

|

94%

|

96%

|

||||

|

双级

|

92%

|

95%

|

||||||

|

平均寿命

|

h

|

|

10000

|

|||||

|

重量

|

kg

|

单级

|

0.4

|

1

|

3

|

5.7

|

12.8

|

|

|

双级

|

0.6

|

1.2

|

3.7

|

7.3

|

17.2

|

|||

|

尺寸代号 |

尺寸名称 |

PS40/NS40 |

PS60/NS60 |

PS90 |

PS115 |

PS142 |

|||||

|

单级 |

双级 |

单级 |

双级 |

单级 |

双级 |

单级 |

双级 |

单级 |

双级 |

||

|

D1 |

输出轴径 |

10 |

16 |

20 |

24 |

40 |

|||||

|

D2 |

止口直径 |

35 |

50 |

80 |

110 |

130 |

|||||

|

D3 |

安装孔中心线圆直径 |

46 |

70 |

100 |

130 |

165 |

|||||

|

D4 |

安装孔径 |

3.4 |

5 |

6.5 |

|

8.5 |

11 |

||||

|

L |

机体长度(不含法兰) |

38 |

51.8 |

53 |

70.5 |

71 |

95.3 |

89 |

120.5 |

120 |

168 |

|

L1 |

输出轴伸长度 |

24 |

25 |

40 |

50 |

80 |

|||||

|

L2 |

键与轴端定位距离 |

2 |

3 |

5 |

7 |

8 |

|||||

|

L3 |

键长 |

16 |

16 |

28 |

32 |

63 |

|||||

|

L4 |

止口高度 |

2.5 |

2.5 |

3 |

3.5 |

3.5 |

|||||

|

L5 |

输出轴肩高度 |

3.5 |

3.5 |

4 |

5 |

5 |

|||||

|

L6 |

安装端面厚度 |

5 |

10 |

12 |

14 |

20 |

|||||

|

B |

端盖宽度 |

40 |

60 |

90 |

115 |

142 |

|||||

|

B1 |

带键轴高 |

11.2 |

18 |

22.5 |

27 |

43 |

|||||

|

B2 |

键宽 |

3 |

5 |

6 |

8 |

12 |

|||||

|

G2 |

轴端孔 |

M3*10 |

M4*12 |

M5*15 |

M6*15 |

M10*25 |

|||||

|

L7 |

法兰厚度(特制法兰数据会有所变化) |

25 |

31 |

40 |

50 |

60 |

|||||

|

法兰连接处的尺寸要求 |

允许电机的输入轴径 |

≤8 |

≤14 |

≤19 |

≤24 |

≤35 |

|||||

|

允许电机的轴长(含止口高) |

25 |

31 |

41 |

53 |

65 |

||||||

|

允许电机的止口尺寸 |

≥27 |

≥38 |

≥51 |

≥70 |

≥90 |

||||||

|

允许电机的外形尺寸 |

≤40*40 |

≤60*60 |

≤90*90 |

≤115*115 |

≤142*142 |

||||||